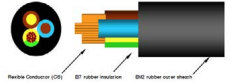

Round Cables

1c 1.5mm2 - 24c 2.5mm2

TPE - Thermoplastic Elastomer

450/750V

TPE - Thermoplastic Elastomer

-40°- 90°C

Excellence and Responsibility

Paige has earned ISO 9001:2015 certification for its factories in Columbus, NE and Silao, Mexico. We are dedicated to ensuring customer satisfaction and continual improvement, while embracing sustainability practices.

You can view our latest ISO Certificates here.